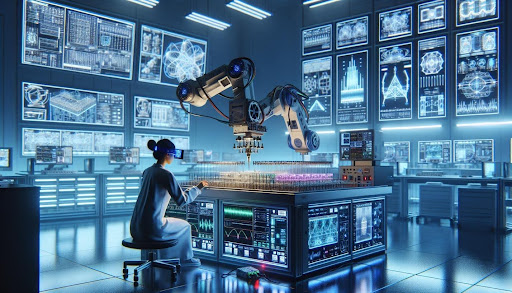

Data acquisition plays a pivotal role in modern test automation, revolutionizing the way industries collect and analyze digital signals. As technology advances, the integration of sophisticated data acquisition systems has become essential for enhancing measurement accuracy and streamlining complex testing procedures. This evolution has a significant impact on various sectors, from aerospace to automotive, where precise and reliable data collection is crucial for innovation and quality assurance.

To optimize automated testing, professionals are turning to cutting-edge data acquisition hardware and software solutions. These tools enable efficient signal conditioning and offer seamless compatibility with graphical programming environments like LabVIEW. By leveraging advanced data acquisition devices, companies can capture high-quality data with unprecedented speed and precision. This article will explore strategies to choose the right data acquisition hardware, improve measurement accuracy, and use data acquisition software to streamline test procedures, ultimately boosting the effectiveness of automated testing processes.

Selecting the Right DAQ Hardware

Choosing the appropriate data acquisition (DAQ) hardware is crucial for optimizing automated testing processes. This selection process involves careful consideration of several key factors to ensure the system meets specific measurement requirements and performs optimally in the intended environment.

Assessing Channel Counts

When building high-performance applications, channel count plays a significant role in hardware selection. The PXI platform offers a solution that maximizes channel density while maintaining a compact form factor. By consolidating redundant components into a single chassis and controller, PXI systems can accommodate up to 544 channels in a 4U rack space. This consolidation not only saves space but also optimizes the number of channels per module, allowing for more efficient data collection in large-scale testing scenarios.

Matching Signal Types

Selecting DAQ hardware that matches the types of signals to be measured is essential for accurate data collection. DAQ systems must be capable of handling various electrical signals and physical-to-electrical transducer outputs. Modern DAQ systems feature built-in digit digital multimeters (DMMs) and signal conditioning circuitry, enabling them to measure multiple signal types without complex setups.

When choosing DAQ hardware, consider the following signal types:

- Analog signals (voltage, current)

- Digital signals (encoders, RPM sensors)

- Temperature measurements

- Pressure and strain gages

- Resistance and capacitance

The ability to handle multiple signal types with universal inputs can significantly reduce costs and simplify system configuration. For instance, a 20-channel universal input card can measure both thermocouple temperature points and voltage points, eliminating the need for separate input cards 2.

Considering Environmental Factors

The operating environment has a substantial impact on DAQ hardware performance and longevity. When selecting hardware, it’s crucial to evaluate the following environmental factors:

- Shock and vibration: For applications involving high levels of shock and vibration, such as automotive testing on tracks, choose systems rated in the 100 g range (EN 60068-2-27:2009) for ruggedness.

- Temperature range: Field testing and environmental chamber experiments often require systems that can withstand extreme temperatures. Look for DAQ hardware with operating temperature ranges from -40° to 80°C (-40° to 185°F) for optimal performance in diverse conditions.

- Dust and water protection: For outdoor or harsh industrial environments, consider DAQ systems with IP65 or IP67 ratings to ensure protection against particle ingress and water damage.

By carefully assessing channel counts, matching signal types, and considering environmental factors, engineers can select DAQ hardware that not only meets their current testing requirements but also provides flexibility for future expansion and adaptation to changing measurement needs.

Enhancing Measurement Accuracy

Calibration Techniques

To ensure high-accuracy measurements, efficient and reliable calibration processes are crucial. Regular calibrations contribute significantly to improving overall product quality and saving time by eliminating non-essential rework. It is recommended that sensors undergo factory calibration at least once a year, depending on their type and usage. For optimal accuracy, sensors should be periodically checked against verifiable reference standards.

Proper sensor handling between uses is vital for limiting the frequency of required calibrations. Sensors should be stored in suitable environments, with batteries kept separately to avoid short circuits. It’s essential to use sensors only for their intended purposes and by trained personnel to prevent damage and maintain accuracy.

Error Analysis

Understanding the electrical environment of an application is crucial for securing measurement success, particularly in noisy or industrial settings. Common sources of error include ground loops, high common-mode voltages, and electromagnetic radiation. To minimize these errors, differential measurements are often preferred. An ideal differential measurement device reads only the potential difference between the positive and negative terminals of its instrumentation amplifier.

However, practical devices have limitations in rejecting common-mode voltages. The common-mode rejection ratio (CMRR) of a differential amplifier determines how much error is introduced by common-mode voltages, varying based on frequency. To develop a valid model for assessing data acquisition error, linear features must be segmented into homogeneous parts and assigned a character.

Noise Reduction Strategies

Several techniques can be employed to reduce noise and enhance measurement accuracy:

- Shielding: Proper use of shielded cables minimizes common-mode electrostatic noise.

- Twisted pair cables: These help eliminate normal mode noise and minimize magnetic fields created by current in conductors.

- Isolation: This technique can dramatically increase the maximum working voltage of a DAQ device, decoupling the maximum working voltage specification from the input range of the amplifier.

- Grounding: Establishing a ground plane helps reduce noise and ensures all circuits have the same reference potential.

- Wire routing: Segregating signal wires from AC and “dirty” power is essential for good signal integrity.

By implementing these strategies and understanding the sources of measurement error, engineers can significantly improve the accuracy and reliability of their data acquisition systems.

Streamlining Test Procedures with LabVIEW

Automating Test Sequences

LabVIEW offers powerful tools for automating test sequences, significantly reducing the time and effort required for manual testing. By leveraging LabVIEW’s graphical programming environment, engineers can create sophisticated test procedures that run automatically, ensuring consistency and reliability in the testing process. This automation capability is particularly valuable for large-scale software testing, where manual methods can be slow and labor-intensive.

Real-time Data Visualization

One of LabVIEW’s key strengths lies in its real-time data acquisition and visualization capabilities. The platform provides a range of tools specifically designed for capturing and displaying time-sensitive data promptly. This feature is crucial for applications that require immediate data processing and analysis. LabVIEW’s waveform charts, for instance, can be configured to maintain a history of data points, allowing users to view both current and past measurements simultaneously.

Report Generation

LabVIEW streamlines the report generation process, offering multiple options for creating comprehensive test reports. Users can generate reports in various formats, including HTML, Automatic Test Markup Language (ATML), and ASCII. The platform also provides flexibility in customizing report content and appearance. For instance, engineers can specify the file path for report generation and choose to view reports automatically after test execution.

To further enhance the reporting process, LabVIEW can be integrated with DIAdem, a specialized tool for report automation. This combination allows for the creation of sophisticated reports that can include detailed data analysis and visualization. By automating the reporting task, engineers can save significant time and ensure consistent, professional-quality documentation of test results.

Conclusion

The evolution of data acquisition systems has a significant impact on automated testing, leading to more precise and efficient processes across various industries. By carefully selecting the right hardware, enhancing measurement accuracy, and leveraging software solutions like LabVIEW, companies can greatly improve their testing capabilities. This approach not only boosts the quality of products but also saves time and resources in the long run.

To wrap up, the combination of advanced data acquisition hardware and software opens up new possibilities to streamline complex testing procedures. As technology continues to advance, it’s crucial for professionals to stay up-to-date with the latest developments in this field. By doing so, they can ensure their testing processes remain cutting-edge, reliable, and capable of meeting the ever-growing demands of modern industries.

Talk to us for more information and reference designs of ATE systems.

FAQs

- What are the essential steps to enhance automated testing methods?

To effectively improve automated testing techniques, follow these key steps:

- Identify the processes that require automation.

- Prioritize and categorize these processes accordingly.

- Prepare by anticipating possible scenarios with test demonstrations.

- Ensure that test cases do not interfere with user interface changes.

- Optimize the data sets used in testing.

- Choose the appropriate tools for your testing needs.

- How do automation and artificial intelligence enhance software testing?

Automation and AI significantly boost software testing by automating routine tasks, which leads to quicker release cycles and enhanced software quality. AI-driven testing tools also aid in detecting and resolving software defects early, preventing them from escalating into more severe problems. - How is test data generation automated?

Automating test data generation involves several steps:

- Step 1: Extract – Identify and connect your automation tool to all necessary data sources.

- Step 2: Manage – Handle the extracted data effectively for your testing purposes.

- Step 3: Provision – Ensure the availability and readiness of data for testing.

- What constitutes an effective test data automation strategy?

Building a robust test data automation strategy involves the following steps:

- Step 1: Define your goals and the scope of automation.

- Step 2: Collect all necessary requirements.

- Step 3: Identify potential risks.

- Step 4: Select which test cases to automate.

- Step 5: Determine the test data and environment needed.

- Step 6: Choose the appropriate technology and framework for automation.

- Step 7: Monitor the progress of testing.

Step 8: Implement a system for reporting results.