Maintenance and Reliability

Increased machine health, uptime, and overall productivity for assets above water or under water.

30%

Increase service life of facility machinery.

20-25%

Reduce maintenance cost.

70-75%

Reduce breakdowns.

35-45%

Reduce downtime.

10 x

ROI

What services do we provide?

Condition Monitoring

Condition monitoring solutions for industrial manufacturing and heavy equipment, even with distributed equipment. Streamline and centralize asset performance data from the field with wireless vibration sensors that collect data from harsh environments and communicate with condition monitoring software to help you predict and prioritize maintenance.

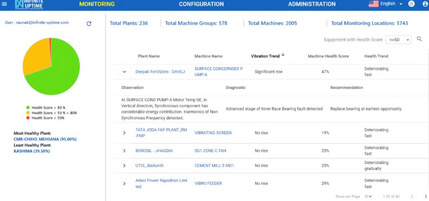

Plant Reliability and Machine Health

Ensure data-driven insights into machine health to avoid challenges such as machine failure and breakdown, unplanned production downtime or increased maintenance cost.

Aquatic drones for water-related assets inspection

Accurate detection of water-related assets conditions such as corrosion, cracks, leaks , thickness and other structural issues, even in the most difficult locations underwater as well as oil and gas pipelines . Quick and complete insight to make data-driven maintenance decisions that minimize downtime and maximize OPEX. See Full Solution

Smart Condition Monitoring

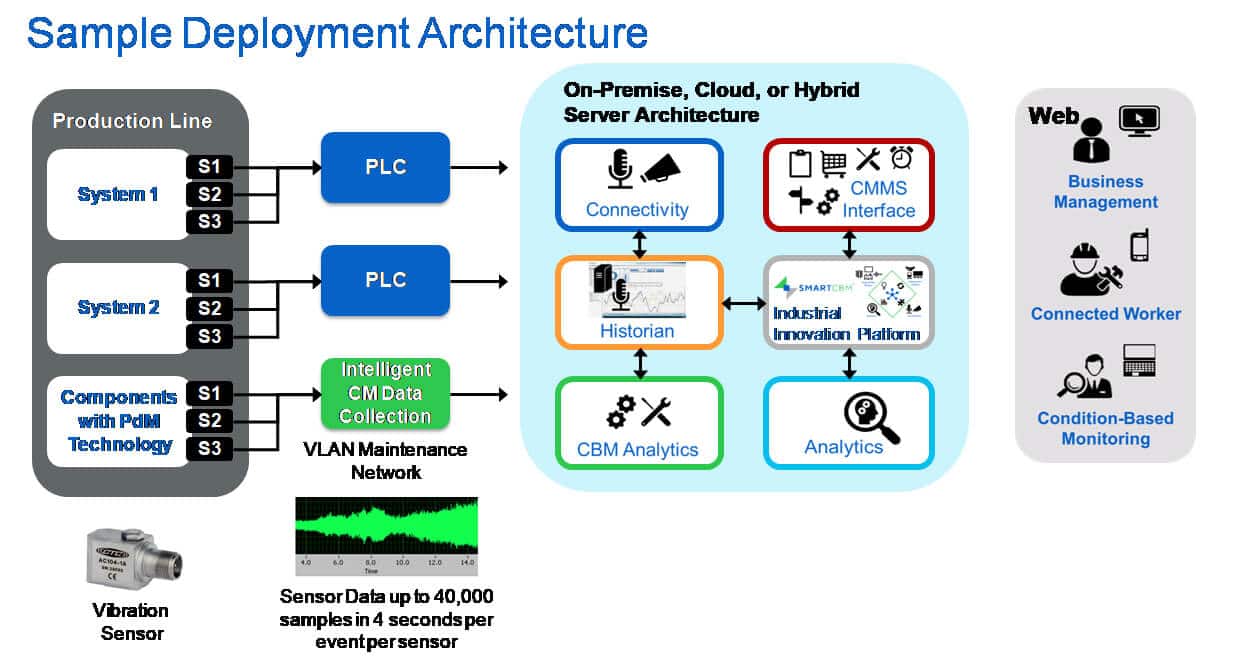

It’s a full suite of PdM Technologies with IIoT capabilities that delivers manufacturing productivity gains while making condition monitoring dramatically more cost-effective. It’s based on early detection of component defects and overall machine condition. What benefits do you get?

-

Less Downtime

-

More Data

-

Wireless Sensors

-

Flexible Deployment Options

-

Fully Customizable to your needs

You can pick the delivery method that is right for you (directed, remote, connected) based on labor cost, personnel and equipment needs, timeline for implementation, and other relevant factors.

Reliability Solutions

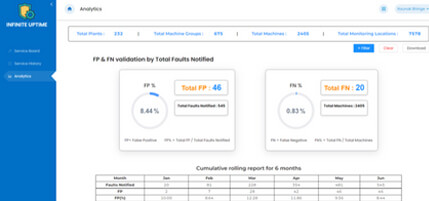

DaaS: Diagnostics as a Service

DRS: Digital Reliability Service

• Transparency Across the Enterprise

• Dashboard with downtime savings data

• Secure, Integrated & Integrable Architecture

• App Suite Built on IU low-code platform

• Energy Monitoring System

• Digitization scale-up with IU low-code platform

• Thousands of hours saved in downtime across plants

Maintenance and Reliability Consulting services

Reliability Systems Review

We examine your maintenance work practices and provide formal feedback to addresses your biggest gaps and most significant opportunities for improvement. We provide you with not only a gap analysis, but an executable project plan that articulates all of the necessary steps to achieve your reliability improvement journey and begin your asset reliability management program.

Other Consulting Services

- Asset Health Assurance

- Coaching and Mentoring

- Equipment Maintenance Plan Development

- Preventive Maintenance Assessment and Evaluation

- Reliabilaity centered Maintenance

- Root cause analysis

- Work Execution management

- Maintenance and reliability training courses, recruiting and staffing.