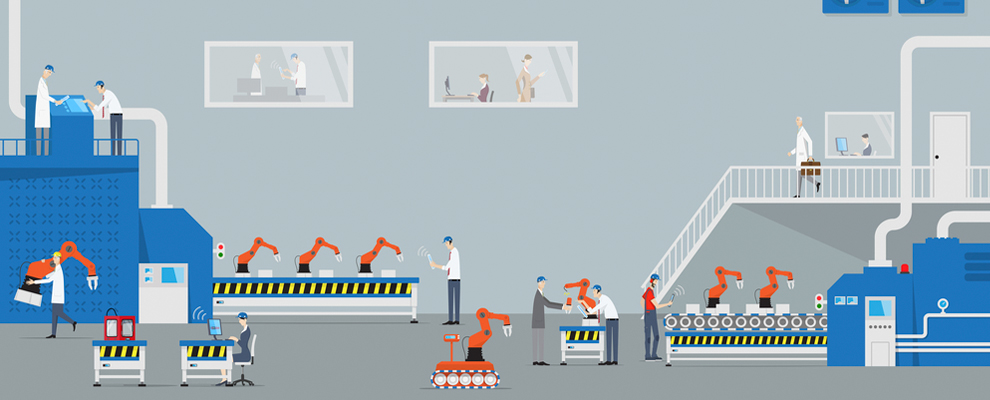

Digital transformation is sweeping the manufacturing world by storm, and there’s compelling reason for this: it allows factories and manufacturers to streamline their systems and deliver greater value to their clients. It also cuts back on overhead, increases revenue, and helps you to get all of your factories on the same page. Smart manufacturing is the way of the future, and embracing it will differentiate you in your field and help you gain more credibility in the long run.

5 Benefits of Digital Transformation for Smart Manufacturing

1. It’s Far More Efficient

The entire aim of digitizing your processes is to look at areas where your business is inefficient or lacking and properly address them. This leads to smoother communication between your supply chain, producers, and your end customers.

By embracing technology that allows you to be more efficient, you are opening up more of your time to focus on other projects and soliciting new clients. You could even explore core elements of your business, like your strategic plan or focus on growth strategies that will allow you to flourish in the future. Since time is your most precious commodity, this is perhaps the biggest advantage to switching to a more digitized manufacturing solution.

2. It Can Automate the Processes in All of Your Factories

If you have multiple factories, you need to consider changing your processes to a digital format. With these new tools, you can link all of your factories together on one central network. This technology can hook up all of your machines, automating certain aspects of production and identifying problems before they become too big to handle. This gives you the ability to embrace fully remote systems as well, monitoring your factories from outside the facility.

By automating certain aspects of production, you are cutting down on the number of worker hours that you need to keep things going. You also keep the production chain moving along rapidly and continue producing in off-hours like weekends, nights, and holidays. Digital systems can also let you know if there is a problem with your factory by sending you a remote alert. You can step in if need be, but otherwise, set and forget it.

3. It Can Reduce Overhead and Costs

You can also digitize your documents, reducing your paper trail, and keeping a record of all factory communication and production reports right in the cloud. This makes it easy to reference and also helps you have the proper documentation for tax reasons.

4. It Can Open Up New Revenue Streams

5. It Can Put Your Company One Step Ahead of the Game

Since this technology allows you to use your data in a more efficient fashion, you can also anticipate industry trends and proactively address challenges as they arise. You can tailor your business to suit these trends through forward-thinking, making you a valuable resource to your clients.

If your manufacturing company hasn’t considered digital transformation yet, it’s time to talk to the experts at SAAB RDS for a technical consultation. Switching to smart manufacturing can do your business a world of good and differentiate you in a very competitive field. Simply exploring your options is the first step to putting together a unique digital roadmap for your company. We work with vendors all across the world and have the expertise and connections to help you succeed. Contact SAAB RDS today to begin your company’s transformation.