Auto manufacturing is witnessing a revolution of sorts, with the advent of cutting-edge technologies reshaping the concept of safety. Embracing digital transformation, the sector is experiencing improved safety measures that have far-reaching implications for efficiency and productivity, from automated test equipment to the use of AI.

The Digital Transformation for Auto Manufacturing

Digital transformation encompasses a wide array of technological advancements, including the Internet of Things (IoT), Artificial Intelligence (AI), Virtual Reality (VR), and Augmented Reality (AR). Each of these technologies brings to the table a unique set of capabilities that can augment operational safety in manufacturing plants.

When properly implemented, digital transformation transcends the traditional boundaries of safety protocols. It not only enhances existing safety measures but also opens up novel avenues for risk prevention, making workplaces safer and more productive.

The Internet of Things (IoT)

IoT holds immense potential to revolutionize safety in manufacturing. This technology leverages internet-connected devices to monitor machinery and processes in real-time. Embedded sensors in manufacturing equipment capture valuable data that, when analyzed, can provide insights into potential safety hazards.

Moreover, IoT enables predictive maintenance by spotting irregular patterns in machinery operations. This allows for timely interventions to prevent equipment failure, reducing the risk of mishaps and enhancing overall safety.

Artificial Intelligence

AI adds a proactive dimension to safety. Traditional safety procedures tend to be reactive, addressing issues as they arise. AI, however, enables manufacturers to anticipate potential risks by analyzing vast volumes of data to identify patterns that humans might miss.

For instance, AI-driven systems can process data from IoT sensors to detect subtle deviations in machine performance that may indicate an impending malfunction.

Virtual and Augmented Reality in Training

Training is a crucial aspect of safety in automotive manufacturing, and VR and AR are transforming how training is delivered, making it more immersive and effective.

VR creates simulated environments that closely mimic the actual manufacturing floor, allowing trainees to gain practical experience without being exposed to real-world risks. AR, meanwhile, overlays digital information onto physical objects, offering instant guidance that enhances understanding of safety protocols.

Automated Test Equipment

A key advancement that bolsters safety and quality control in manufacturing is the integration of Automated Test Equipment (ATE). In the realm of safety technologies, ATE provides efficient, accurate, and reliable testing of electronic devices and systems used in automobiles.

ATE systems are computer-controlled, which ensures a high degree of precision and repeatability. They are designed to perform tests on various devices, such as circuit boards, chips, and complex integrated circuits, to ensure they function correctly and meet specified safety and quality standards. ATE can identify potential issues that might lead to failures in real-world situations.

Furthermore, ATE brings speed and efficiency to the testing process, especially when used in conjunction with the technologies already described. Given the large volume of electronic components in modern vehicles, for example, manual testing is both time-consuming and prone to human error. Automation allows manufacturers to perform comprehensive testing quickly, increasing throughput without compromising safety or quality.

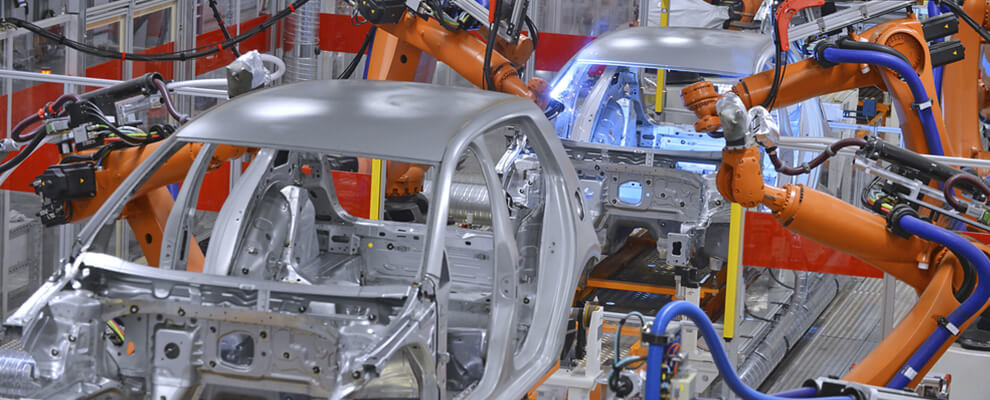

Advancements in Robotics and Automation

Robotics and automation are already symbols of technological progress in vehicle manufacturing. From assembly line robots to automated guided vehicles, these technologies play a critical role in ensuring safety: and more now than ever.

Robots can undertake high-risk tasks, such as handling heavy equipment or working in hazardous conditions, thereby minimizing human exposure to potentially dangerous situations. Likewise, automation reduces human error, which is a significant contributor to accidents. By relieving workers from monotonous and physically demanding tasks, automation reduces fatigue-related mishaps, contributing to a safer workplace.

Big Data for Enhanced Safety

By processing and analyzing massive volumes of data collected from the production floor, manufacturers can now quickly glean critical insights into potential safety issues. This includes everything from identifying recurrent machine malfunctions to uncovering subtle correlations that might point to hazardous conditions.

Advanced analytics can then help extrapolate trends, predict future risks, and set the groundwork for proactive safety measures. Harnessing the power of Big Data presents auto manufacturers with an opportunity to reimagine safety protocols, preventing accidents before they occur and ensuring a safer working environment.

SAAB RDS and Your Digital Transformation

Embarking on a digital transformation journey requires a partner with sound technical expertise and a customer-centric approach. At SAAB RDS, we tick both boxes. Our deep-rooted understanding of digital technologies and hands-on experience across multiple domains make us the ideal partner for your digital transformation needs. We work with an array of vendors, ensuring that we can help you build a comprehensive, customized framework that aligns with your specific needs.

Our relationship with customers is a partnership, so your success is our success. We offer our services as SaaS, allowing for seamless integration and scalability. Above all, we prioritize the human touch. Despite operating in a tech-driven industry, we recognize the value of human involvement in fostering meaningful relationships and delivering superior service.

Ready for the Revolution?

The manufacturing industry is on the brink of a safety revolution fueled by technological advancements. From IoT to AI, VR, and AR, these digital tools are redefining safety testing, norms, and protocols, making workplaces safer and more efficient. Our unique blend of technical expertise, multi-vendor approach, and commitment to customer satisfaction sets us apart. We offer a human touch in a technology-driven world, ensuring a balanced and holistic approach to your digital transformation needs.

Embracing digital transformation is not just an option, but a necessity for survival in today’s competitive manufacturing landscape. Get in touch with us at SAAB RDS for a technical consultation and take the first step towards a safer, more efficient future.