In the aerospace industry, precision, reliability, and safety are nonnegotiable. Every component, from avionics to propulsion systems, must operate flawlessly under the most extreme conditions. As the demand for advanced aerospace technology grows, enhancing your testing capabilities becomes essential. Automated Test Equipment (ATE) plays a vital role in supporting advanced aerospace technology by delivering precision automation, real time data analytics, and the adaptability needed to meet evolving challenges. Whether it is for flight control systems, communication modules, or engine diagnostics, ATE ensures every part of your system aligns with the standards of advanced aerospace technology, helping you innovate with confidence and push performance boundaries.

Automated Test Equipment in Advanced Aerospace Technology

Achieving Precision

Even the smallest defect can have catastrophic consequences, and ATE delivers the precision you need to test these increasingly complex systems with exacting accuracy. ATE systems automate test sequences and measure parameters like signal integrity, power output, and thermal performance with pinpoint precision. In doing so, they eliminate one of the biggest frustrations: the possibility of human error. ATE allows you to validate components against the tightest tolerances with consistency.

Accelerating Testing

Your aerospace projects are always under intense pressure to meet tight development timelines, and manual testing methods can slow you down; but ATE streamlines the process by automating all the repetitive and complex tests. In doing so, it allows you to slash testing times without sacrificing thoroughness. For example, ATE could be set up to run simultaneous tests on multiple subsystems at once, collecting real-time data along the way. This speed then allows you to quickly iterate designs and address any issues before they escalate.

Compliance

Aerospace manufacturing is subject to a complicated web of regulatory requirements, from FAA certifications to military specifications, and one of the great advantages to ATE is that it simplifies compliance by providing comprehensive traceability and documentation. Every test result is logged with detailed data, and this creates an audit trail that lets you instantly demonstrate that you’re following all industry standards. If a question arises about a component’s performance, you can quickly retrieve test records to verify compliance. This transparency not only reduces the risk of costly penalties but also builds trust with customers and regulators.

Enhancing Reliability

Aerospace systems have to be able to withstand the harshest of environments. They’re going to need to be able to operate under extreme temperatures while enduring constant vibrations and even radiation. ATE enables you to simulate these conditions during testing, over and over again, to see how your components will perform in the real world: not just once but over the course of years. By subjecting parts to stress tests, such as thermal cycling or electromagnetic interference, ATE allows you to identify weaknesses before they become failures so you can refine your designs and improve durability.

Scaling Testing for Complex Systems

Aerospace projects are growing in complexity each year, yet each of these integrated systems demands rigorous testing at every stage. Automated Test Equipment (ATE) is built to handle this need to scale. From testing individual circuit boards to validating entire avionics suites, ATE adapts because its modular design lets you expand testing capabilities as your projects evolve.

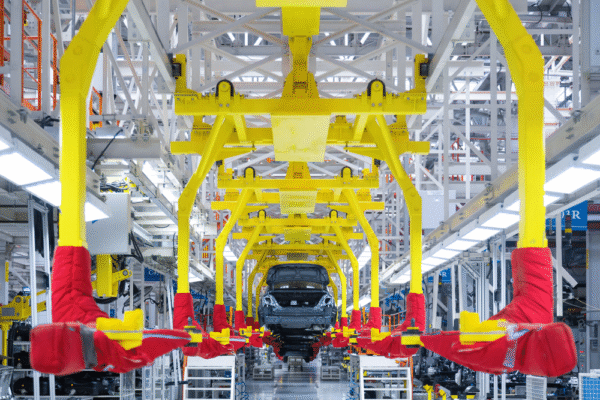

Integrating with Smart Manufacturing

If you’re adopting smart manufacturing to enhance efficiency, and you should be, know that ATE is made to integrate right to this connected ecosystem. By linking with IoT, AI, and advanced analytics, ATE can gather up all the data it needs to give you insights into your production line and optimize your testing and production processes. For instance, say that ATE detects a recurring issue in a component. By gathering all the data and then sharing it across your manufacturing network, you can quickly pinpoint the root cause, which might be anything from a supplier issue to an assembly error.

Reducing Costs

ATE delivers cost savings by streamlining the testing process, minimizing the need for human intervention, and minimizing waste all along the way. Automated systems reduce the need for labor-intensive manual testing, which means you need fewer people and can focus on those highly skilled engineers you need for the high-value tasks, like design innovation. Additionally, by catching defects early, ATE can keep you having to go with a costly rework or even experiencing a field failure that could damage your reputation. The data from ATE also helps you optimize manufacturing processes so you have less material waste and better efficiency generally.

Supporting Innovation

You can’t innovate to use lighter materials or more efficient propulsion systems unless you have a way to do reliable testing. ATE empowers you to push the limits of aerospace design by providing precise, repeatable test results and a simple, cost-effective way to test just about anything. For example, if you’re prototyping a new radar system, ATE could simulate operational conditions to validate performance in a space where you can “fail” as often as you need to in order to refine and create. ATE’s flexibility even allows you to test emerging technologies, such as advanced composites or autonomous flight systems, without sacrificing reliability.

Better Collaboration

Any aerospace project is going to involve multiple teams, from engineers to quality assurance and production staff, and you want them all working toward a common goal. Unfortunately, that’s often easier said than done; but ATE helps by providing your teams with a centralized platform for testing data. Test results are instantly accessible, so teams can analyze performance in their niche, identify issues, and implement solutions together. The point is to make miscommunication less likely and accelerate problem-solving.

Future-Proofing

ATE is designed with adaptability in mind. It’s installed with the intention not only to test existing systems but also to be ready to go on emerging technologies as they arrive. The customizable architecture allows you to update test protocols whenever you need so you can stay cutting-edge without having to re-invent the wheel every time.

The future is now, and SAAB RDS is your technology partner to help you experience it all. Visit SAAB RDS now to see how we can simply your complex needs.