From virtual assistants that can answer questions, to autonomous drones that can fly and unpack boxes, AI is transforming the way we work and the tools we use in our everyday jobs. The global AI market is currently worth $136.6 billion according to GrandViewResearch: the global AI market size was valued at USD 93.5 billion in 2021 and is intended to expand at a CAGR (compound annual growth rate) of 38.1% from 2022 to 2030.

The Tech giants are driving the adoption of advanced technologies in industry verticals thanks to continuous research and innovation. Industries such as automotive, healthcare, retail, finance, or manufacturing are seeing the number of AI projects and use cases multiplied, from self-driving vehicles to crucial life-saving medical gear or automation of customer care operations.

Key factors that are driving the artificial intelligence market growth include a rise in the adoption of big data, analytics, and the increasing potential of R&D in developing AI systems and technological innovations across the globe.

Indeed, 40% of organizations have thousands of AI models deployed (in 2022), and leading organizations expect to double (x2) the number of artificial intelligence (AI) projects in place according to a recent Gartner survey.

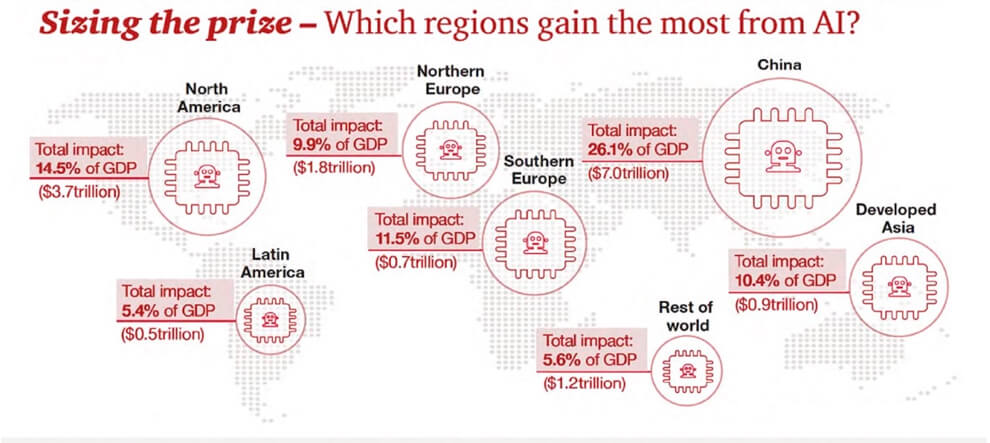

Regional breakout of AI contribution to the Global Economy

PwC Global Artificial Intelligence Study shows that AI has a $15.7 trillion potential contribution to the global economy by 2030.

45% of total economic gains by 2030 will come from product enhancements, stimulating consumer demand. This is because AI will drive greater product variety, with increased personalisation, attractiveness, and affordability over time. While all regions will benefit from this contribution, The greatest economic gains from AI will be in China (26% boost to GDP in 2030) and North America (14.5% boost), accounting for almost 70% of the global economic impact.

AI Impact on the workforce

According to a 2020 World Economic Forum report on the future of jobs, although 85 million jobs will be displaced by automation and Artificial Intelligence advances by 2025, in parallel, 97 million new roles will be created by 2025 to fill the work demands of the surging industry (The World Economic Forum).

In this landscape, it is more important than ever to ensure proper training and skills development both at universities and for the current workforce. As a matter of fact, AI and other recent technologies such as Virtual Reality (VR) or Augmented Reality (AR) are proving key to the development of these skills for the workforce (see the example of the connected worker).

Industrial AI

As already said, AI is impacting a variety of industries, including manufacturing and industrial IoT. Industrial AI is a branch of artificial intelligence focused on creating digital versions of physical objects so that they can be operated remotely or autonomously as part of a network. It uses computer vision, speech recognition, natural language processing, and more to create virtual representations of industrial machinery. This allows for more operational flexibility with fewer humans present on site.

In fact, the manufacturing industry stands out in the AI landscape, as it’s set to gain $3.78 trillion from AI by 2035 (Accenture). This research shows that Information and Communication, Manufacturing and FinancialS ervices are the three sectors that will see the highest annual GVA (gross value added) growth rates in an AI scenario, with 4.8 percent, 4.4 percent and4.3 percent respectively by 2035.

In Manufacturing, precursors like the Internet of Things (IoT) create favorable conditions

for the seamless integration of intelligent systems. Today’s IoT technologies enable physical devices such as assembly lines to connect and communicate with digital systems. Moreover, AI can bridge the gap between current forms of automation and learning with more advanced forms. Gart research shows that AI could add an additional US$3.8 trillion GVA in 2035 to this sector—an increase of almost 45 percent compared with business-as-usual.

What AI trends are bringing growth in Manufacturing?

Industrial manufacturing is where AI truly came from. In the 1950s, computer scientists began to model artificial neural networks, or ANNs. These networks were designed to simulate the connections between neurons in the brain. Researchers applied ANNs to industrial use cases, like controlling the temperature of a smelting furnace, forecasting demand for a product, or detecting defects in a manufactured part. ANNs continue to underpin AI for manufacturing today. While the basics of AI for manufacturing remain the same, the technology has advanced quite a bit over the past few decades. Today, AI solutions for manufacturing include machine learning, natural language processing, robotics, and autonomous vehicle systems.

Automated Processes

Manufacturing has a long history of automating processes. Today, AI has given rise to a new wave of industrial automation. These AI-powered systems use algorithms to make decisions. They collect data, analyze it, and learn from it to make better decisions over time. A perfect example of how AI is automating processes in industrial manufacturing is Predictive Maintenance: Predictive maintenance uses data to determine which pieces of equipment need maintenance, as well as when they need it. It helps determine the condition of your high-value assets, alerting you to the presence of a machinery defect, and it can also recommend specific repairs to extend the lifetime of equipment, decreasing downtime and more importantly, increasing uptime and productivity of the manufacturing line.

Robotics and Autonomous Vehicles

Robotics and autonomous vehicles are two of the most exciting areas of AI for manufacturing: as AI continues to advance, it is increasingly being used in industrial robotics to add more flexibility and adaptability to the environment While humans have operated robots in manufacturing for decades, AI now allows for robots to be able to learn and analyze data to make decisions on how to best complete tasks. I-powered robots can detect their environment, identify human operators, and make decisions based on a variety of factors. AI can also be used to make robots safer by giving them the ability to recognize hand gestures and natural language. This can be helpful in situations where the environment is potentially dangerous for humans.

AI-powered autonomous vehicles are another great example of AI’s potential in manufacturing. Autonomous vehicles are designed to operate without human input — they may collect data, analyze it, and drive themselves to a destination. AI-powered autonomous vehicles can navigate complex environments like dense cities. They can detect changing weather conditions like fog or heavy rain, navigate around obstacles like construction workers and potholes, and stay on course. More than ever before, autonomous vehicles are allowing manufacturers to service customers in new markets.

The Specific Case of Autonomous Drones

Drones have become increasingly common in industrial settings, especially in areas with limited accessibility. While they can perform tasks autonomously, they are not able to learn and adjust based on feedback. Drones that use AI can identify objects and other factors in their environment, such as weather conditions. They use this information to adapt their flight path and select the most efficient route to complete a task. This allows them to be more flexible and accurate in their work. Drones that use AI can also be programmed to recognize and respond to certain gestures and other forms of input, such as hand signals. This can be helpful for when there is a risk of causing noise, or when it would be difficult to communicate with the drone verbally.

AI and Robotics Together is the Future

Currently, AI and robotics are being used separately to varying degrees in a number of different industries. But as levels of AI continue to rise and become more sophisticated, a number of companies are experimenting with bringing the two together in a new way. Industrial robotics that also have AI capabilities are able to learn and observe sensor data in order to assess whether changes should be made to their process or environment. This makes them more flexible and agile, allowing them to shift and adjust based on the information they receive. This is particularly useful in environments that are subject to change a lot, like construction sites. By having an AI-enabled industrial robot, you can replace a sensor that has stopped working with new data with ease, without having to spend extra time and money replacing the entire system.

Final Words: Artificial Intelligence is Here to Stay

Artificial intelligence has come a long way in a relatively short period of time. New applications for AI are being discovered and developed all the time, and the technology is expected to continue growing and advancing at a quick pace. Industrial AI has come to the forefront as one of the most important uses of AI. It allows industrial machinery to be operated remotely and autonomously, with fewer humans present on site. This has a number of benefits, including increased accuracy and flexibility, as well as safety. Automated vehicles are another key application of industrial AI that has received a lot of attention in recent years.

Artificial intelligence has the potential to change every industry. These changes are happening now, and they will continue to accelerate in the coming years. The industrial world is a key area of development for AI: more than ever before, manufacturers need technology that can keep up with rapidly changing markets, new materials, and consumer demand. AI is that technology, and it is already showing an impact on operations, costs reduction, and capturing new opportunities with intelligent automation and data-driven decision making.