As major markets show increased concern for environmentally friendly practices, companies worldwide are being forced to consider ways to make their products more ethical and sustainable. Product Lifecycle Management, or PLM, has become an important topic within sustainable manufacturing. At its core, the problem is that most companies don’t consider what happens after a product is used. Both consumers and governments are looking to change that. How can you prepare your company for these changes and become more sustainable?

Product Lifecycle Management and Sustainable Manufacturing

A Growing Priority for Customers

At the moment, there aren’t any strict laws that impose PLM practices on manufacturing companies. For the most part, efforts are focused on eliminating bad practices that produce waste in the first place. Perhaps the most recent example comes from the EU, where Apple was forced to use a common USB-C connector instead of a proprietary cable for its phones. Both governments and private businesses in the EU and other regions likewise expect similar commitments to sustainability from their partners.

Those expectations abroad are precisely what led to several Middle Eastern nations adopting better sustainability standards. One of the main obstacles is waste production. Countries like Saudi Arabia, UAE, and Bahrain have some of the highest waste outputs per capita. Their governments want to support companies that close the cycle and reduce waste. What does your business need to do to make it more attractive given these new priorities?

Challenges Involved in PLM and Sustainability

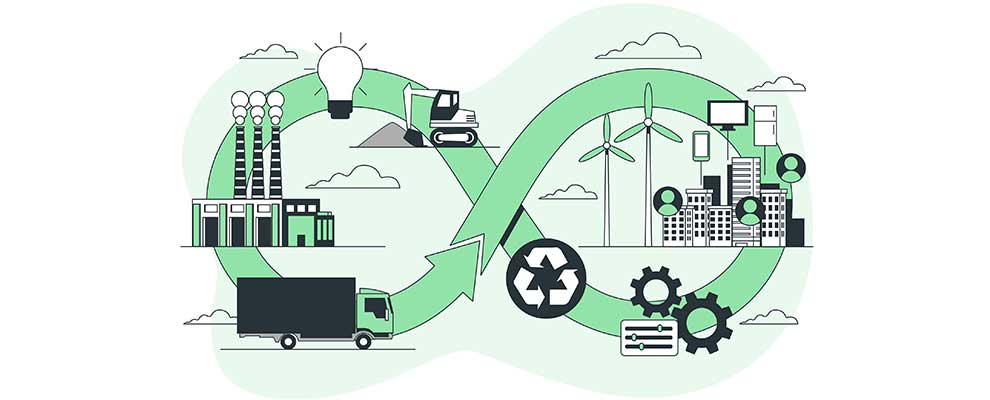

Product lifecycle management requires that companies think beyond the main application of their product. They have to consider what will happen with the product after it’s been used. Ideally, companies will create some kind of mechanism to properly dispose of or reuse their products after they’ve been expended. By reducing waste output, manufacturing becomes more sustainable as it consumes less resources.

Nevertheless, this poses several problems for businesses. Consider some of the challenges involved in adopting sustainable practices and how your company can overcome them.

Impact on Profits and Sales

Many companies fear that PLM initiatives will severely impact their profits. However, the exact opposite is true. It turns out that deliberately focusing on your product lifecycle can actually boost profits and improve productivity. For example, you may find that your product can last much longer with a change in materials. This could position your product as more reliable and sustainable, leading to increased sales.

Cost-cutting is also possible despite some additional initial spending on lifecycle assessment (LCA). PLM tools give you a clearer picture of your supply chain, which can help you identify ways to cut waste in the procurement and production process. Even though PLM initiatives largely focus on the end-life portion of the cycle, there are savings to be had throughout.

Manufacturing Difficulties

Sustainable manufacturing methods may call for new techniques or different materials to be used in your products. For instance, many plastic bottle manufacturers have switched to biodegradable materials to reduce landfill impact. Others have looked to reduce the amount of material they use. In any case, new manufacturing processes may have to be designed.

You can speed up this process and evaluate many possible methods by using simulations. Digital test beds can be configured to test out various designs before setting up a production line, allowing you to narrow down your options and choose the most viable designs that have the best ecological impact.

Closing the Loop

If you’re involved in aerospace or automotive manufacturing, PLM and sustainability may seem nearly impossible to achieve. After all, most of the components you produce are meant to be used for years, if not decades. Sustainability requires closing the loop by reusing or recovering the original material. How do you close a product cycle after so much time has passed?

Closing the loop can create opportunities for repeat business. Offer to take excess inventory off customers’ hands when they make a new purchase. Consider rebates for returned parts, even if used. By encouraging the components to return to you, rather than dumping them somewhere, you can get more accurate data for future sales and help customers avoid wasted orders. That commitment can result in better sales in the future.

Potential Benefits to Consider

While there are definitely hurdles to overcome in implementing proper product lifecycle management practices, there are benefits that make it worthwhile. In particular, the choice to embrace sustainable manufacturing can have a significant impact on your public image. Furthermore, implementing PLM systems in your company can help you digitize other aspects of your supply chain management and optimize your processes for long-term growth.

Brand Loyalty

Consumers are pressuring companies to be more socially and environmentally responsible. If you market products directly to your consumers, highlighting your sustainable practices can provide a boost to your image. It’s not enough to just try to sell a sustainable product: you have to couple it with effective messaging. Even if your business is further down the chain, your clients may find it difficult to business with companies that don’t uphold commitments to sustainability.

By investing in the right tools now and being an early actor, you can garner attention that can convert more people into clients and build greater brand loyalty.

Long-Term Growth

As governments and larger organizations push more climate initiatives, there will be benefits for those that adhere to protocols, and punishments for those who do not. Carbon taxes, for example, could lead to a sudden spike in costs. By taking action now to mitigate those risks, you position your company for success in the long term. Conversely, you will be more likely to secure lucrative contracts as a sustainability leader. So, what do you have to do?

Crucial to achieving proper PLM practices and sustainability is digitizing your workflow and tracking your products throughout their entire lifecycle. Contact SAAB RDS to learn how we can help you implement the right tools to make your company sustainable in the face of a changing future.