Automated Test Equipment

Transform Your Electronics Development with Advanced ATE Platforms

Welcome to the future of electronics system design and test. Embrace the power of Automated Test Equipment (ATE) platforms to dramatically accelerate your design cycles, ensuring faster validation, quicker verification of design requirements, and reduced time to market. Our high-performance, cost-optimized systems are tailored to meet aggressive product development schedules, enabling you to develop electronics products locally.

Localize Technology, Maximize Efficiency

By integrating ATE into your processes, you’re not just adopting new technology—you’re fostering local capabilities and securing intellectual property. Our platforms are designed not only to streamline product development but also to empower your teams to develop and refine technologies locally. With ATE, you can enhance every phase of your product’s lifecycle, from conception to production, ensuring quality and efficiency at every step.

Automated Test Equipment – Featured Technologies

- Standardized mechanical, power, and safety infrastructure.

- Layout flexibility for PXI, CompactDAQ, CompactRIO, and other instrumentation with preinstalled drivers.

- Emergency shutoff, thermal shutdown, and power and Ethernet routing

- Power and size options from 24U to 40U and low, medium, and high power, both single- and three-phase.

- IEC 61010-01 compliant system that can be shipped anywhere in the world with expedited delivery options.

Specific components for Automated Test Equipment

- Power Entry Panel: contains IEC connector, circuit production, line filters, kill-switch relays for emergency shutoff, two USB extension ports, an Ethernet port to route network connection to the Ethernet switch, and an external grounding lug.

- Power Distribution Unit: Each single-phase PDU contains eight IEC C13 outlets, four DC outlets (12 V, 24 V, 24 V, 48 V), two power-sequenced outlet banks, circuit protection, and remote inhibit and emergency power off.

- Emergency Power Off Panel and Uninterruptible Power Supply, to optimize safety during both normal operations and special conditions such as power loss or brownouts.

Services and support:

- Reduce Downtime: Expedited repair, managed spares, on-site calibration, life-cycle management services, and preventative maintenance.

- Professional Services: Consulting, system integration, and software library development.

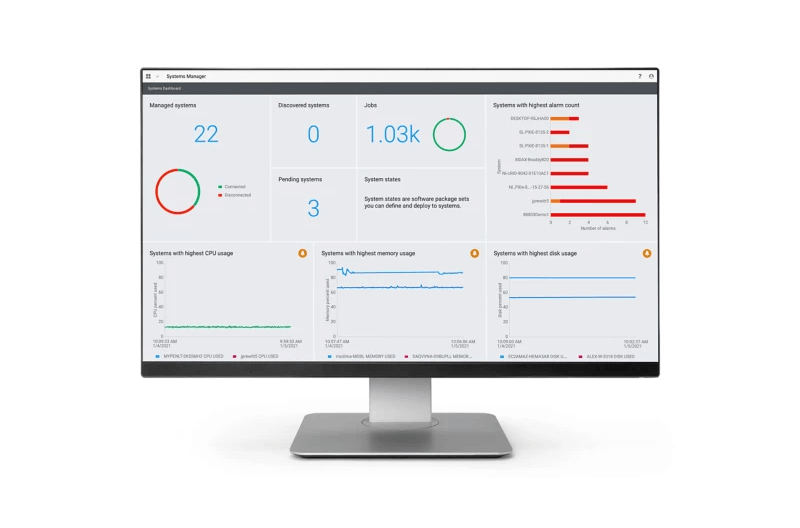

Test Software

Software is the key to flexibility in an ATE system. In addition to designing your test application, you most probably will need a software to manage (develop, debug, and deploy the test system) your test with full visibility into the testing process and results; or to measure data aggregation, inspection, analysis, and reporting. A good cost-effective option is to get a bundle that contains all these software capabilities: Test Workflow is a recommended collection of NI software for engineers working on research, validation, and production test applications.

Test Workflow provides application-specific tools so that you can choose the right one for the job you need to accomplish—from graphical programing environments to no-code and interactive software applications which allow you to perform everything from a quick ad-hoc test to buildin a full automated test system, and also automate data analysis and reporting, develop test sequences, etc.