Predictive Maintenance Solution

Improve your plant reliability and machine health

Achieving plant reliability and ensuring asset availability are top priorities for maintenance and operational leaders as the industry moves towards digital transformation and sustainable manufacturing practices. However, the lack of data-driven insights into machine health can significantly impact plant reliability, leading to various challenges such as:

- Machine failure and breakdown

- Unplanned production downtime

- Increased maintenance cost

- Uncontrolled resource wastage

- Hazardous working environment

- Potentially catastrophic events risking life and property

Research shows that more than 70% of equipment breakdowns are caused by mechanical faults including wear and tear, deterioration over time, backlash in components, increased clearances between parts resulting in vibrations and acoustics-related issues. Inefficient maintenance strategies not only reduce a plant’s overall production capacity by 20-30%, but they can also bring production to a complete halt for weeks. Without an effective solution in place, maintenance teams struggle to develop responsive maintenance strategies that align with their plant reliability objectives.

We partner with Infinite Uptime, a global Predictive Maintenance Services and Plant Reliability solutions company to help maintenance and manufacturing teams to attain the highest level of plant reliability by reducing unplanned downtime, mitigating operational risks, and improving overall efficiency.

Industrial Data Analytics Platform (IDAP)

Industrial Data Analytics Platform (IDAP), is a comprehensive solution designed to address these challenges in industries such as metal, cement or chemicals manufacturing:

- Real-time condition monitoring with cloud data backup

- Smart dashboard for live monitoring and predictive data analytics

- Syndicated fault diagnostics and prescriptive recommendations

- Subscription-based OPEX model for standard and non-standard equipment

- Digital twin scenario reports with actionable insights

- Fault notification and alerts with fault-specific recommendations

- Prediction of RUL and downtime to support maintenance planning

- Post maintenance procedure and health score improvement reports

A complete data-driven approach to plant reliability is adopted to offer real-time insights into equipment health and enriched information to improve failure predictability. A sophisticated solution architecture allows us to monitor mission-critical assets across production environments. Solutions engineered for specific applications generate advanced analytical insights from real-time diagnostic data.

Our responsive digital reliability solutions are tailored to provide customers with:

Remote Condition Monitoring

Monitor plant performance from anywhere, anytime, and on any device with complete visibility.

Data-Driven Machine Diagnostics

Get meaningful and decisive insights from the sheer volume, velocity, veracity, and variety of machine data.

Digital Reliability Services

Intelligent data analytics to detect anomalies in the operation process and potential faults in equipment to predict maintenance requirements and prescribe corrective actions.

THE SOLUTION

Reliability Reporting

- Differentiate between anomaly detection and fault detection with False Positive and False Negative indicators

- Access visual spectrum reports for a ‘Before Repair’ & ‘After Repair’ effect and calculate the exact downtime impact across every production line and plants

- Get vital information on investigations, treatments, or operations to be performed using the Observation, Diagnostics Recommendation (ODR) module

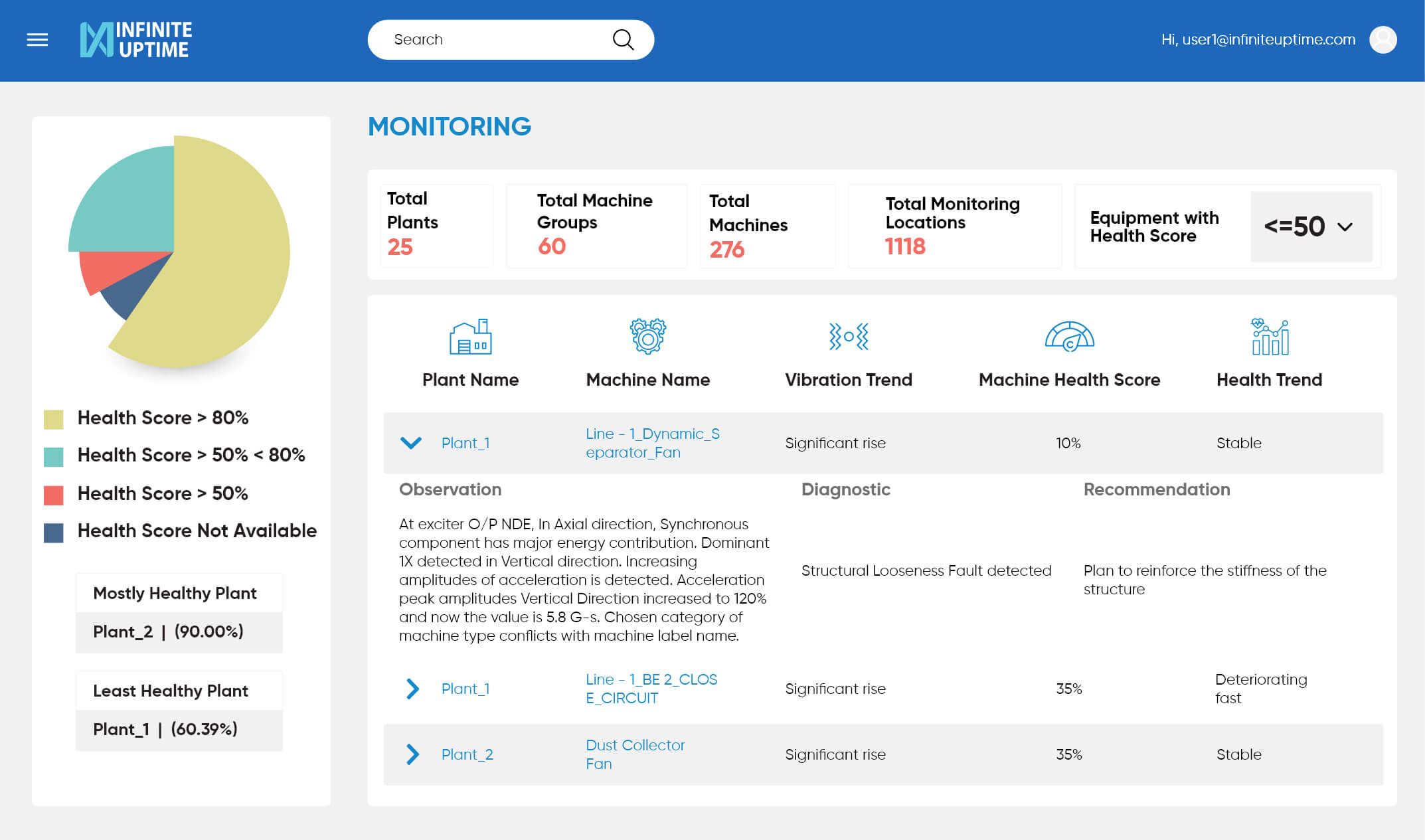

Detailed Plant View

- A complete view of your plant performance across locations and machine groups.

- Track your plant KPIs with summarized and dashboard views

- Prioritize your maintenance activities based on the equipment’s health status.

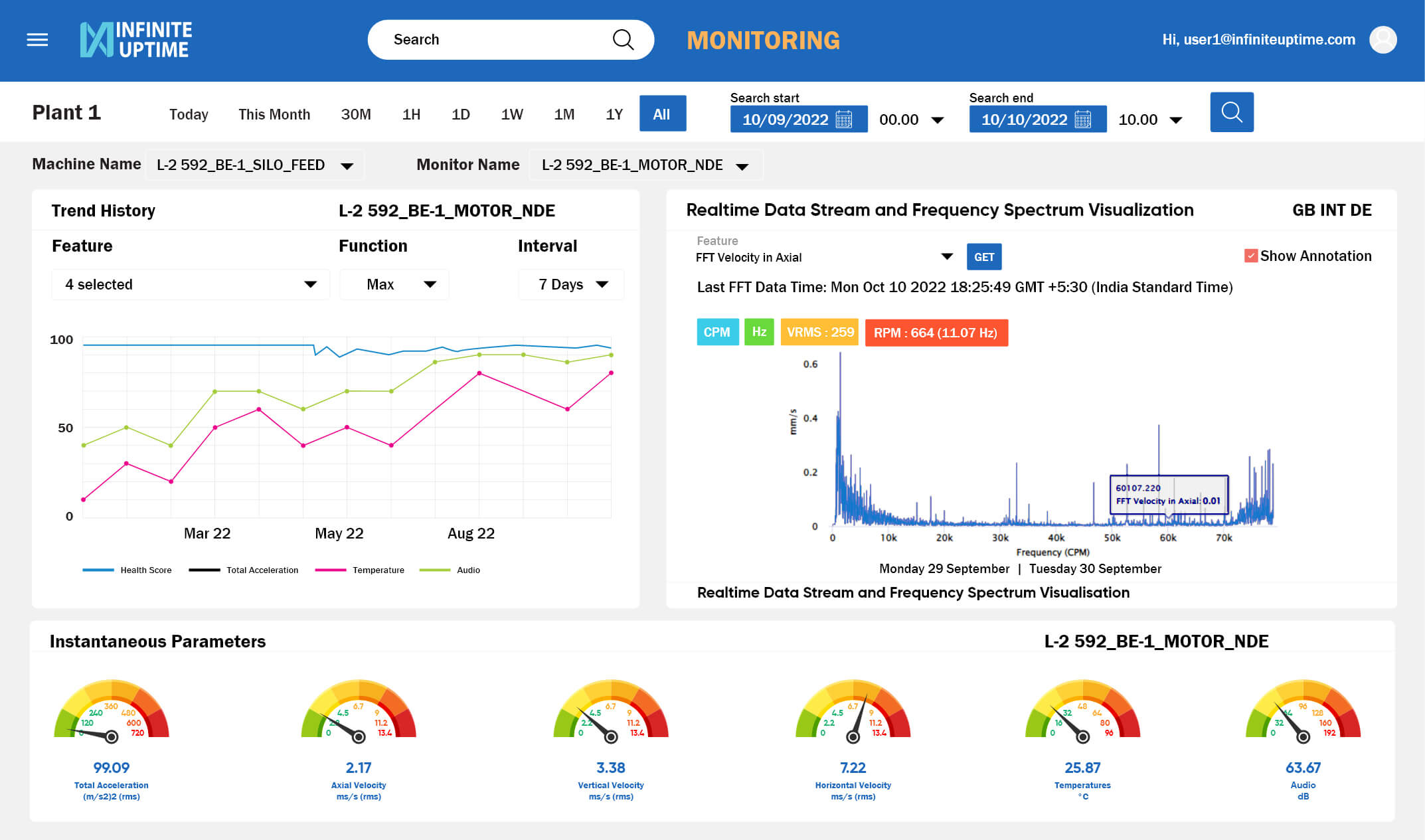

Trend Analysis

- Access trend history of critical parameters like Health Score, Velocity, Acceleration, Temperature, and Acoustics.

- Get detailed footprints and time series data of FFT waveforms & spectrum for analysis

- Maintenance index for condition monitoring teams to decide actions based on alarm status