Feb 20, 2023

The aerospace industry relies on Automated Test Equipment (ATE) systems to enhance testing efficiency, accuracy, and reliability. These systems are an integral part of modern electronics manufacturing, as they help reduce the time and effort required to test each device while providing valuable insights into the manufacturing process.

Oct 21, 2022

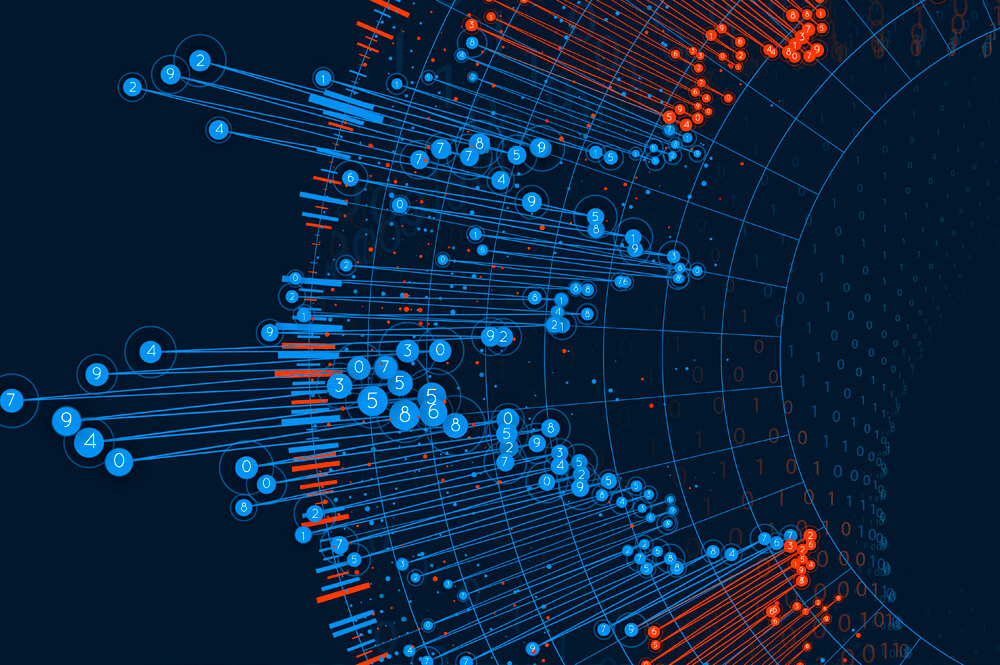

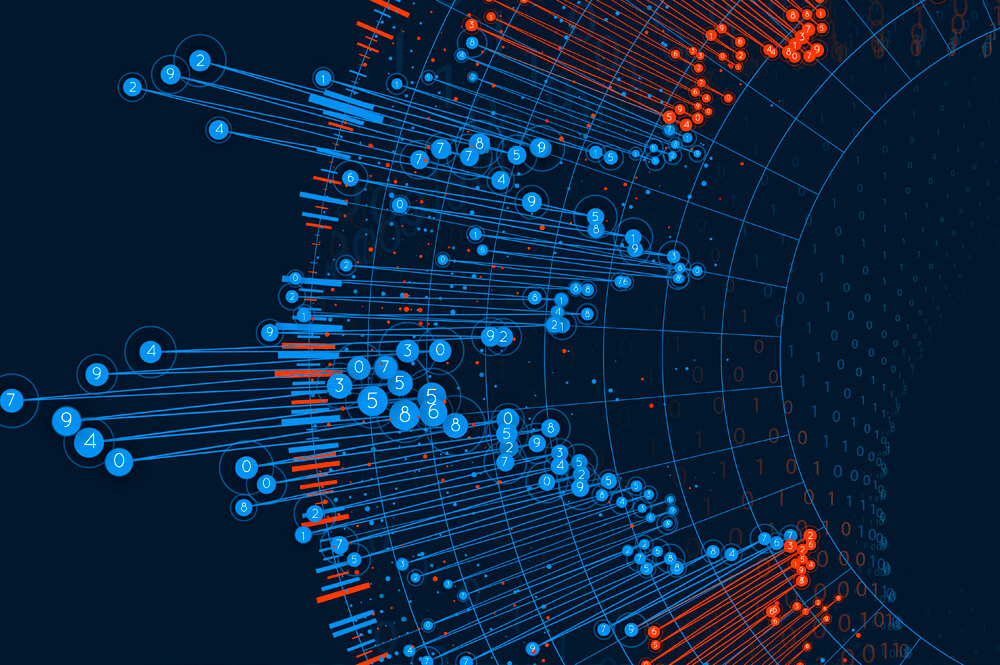

Data is the fuel for the right business decisions. If you want your team to make informed decisions, you need to collect, store, and analyze data. In production test, the key to achieving success is using standardized processes, systems, and data to improve development productivity, test station design quality, and operational efficiency.

Aug 16, 2022

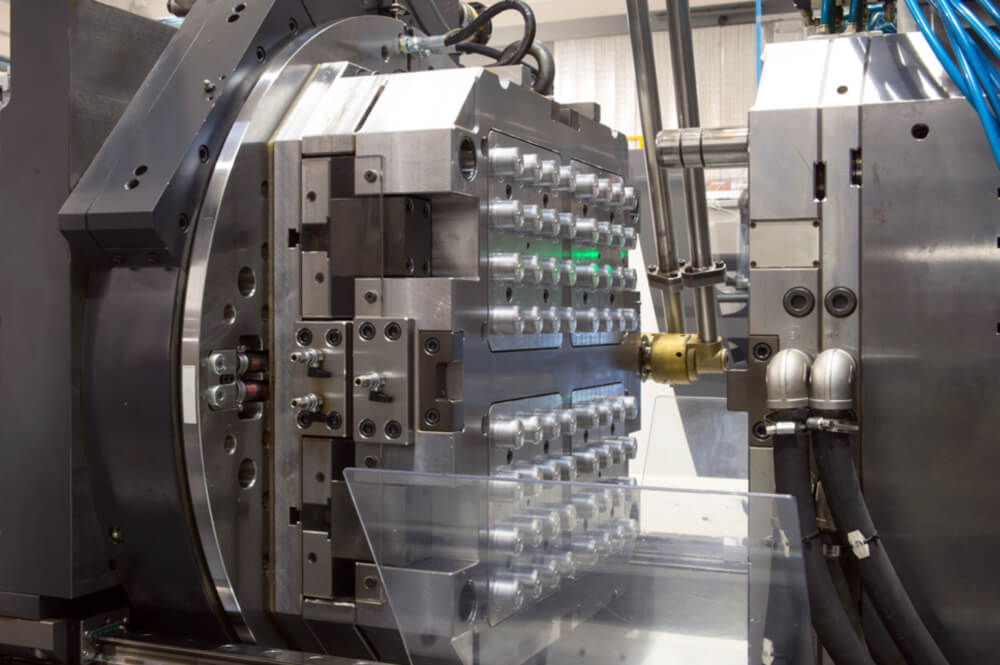

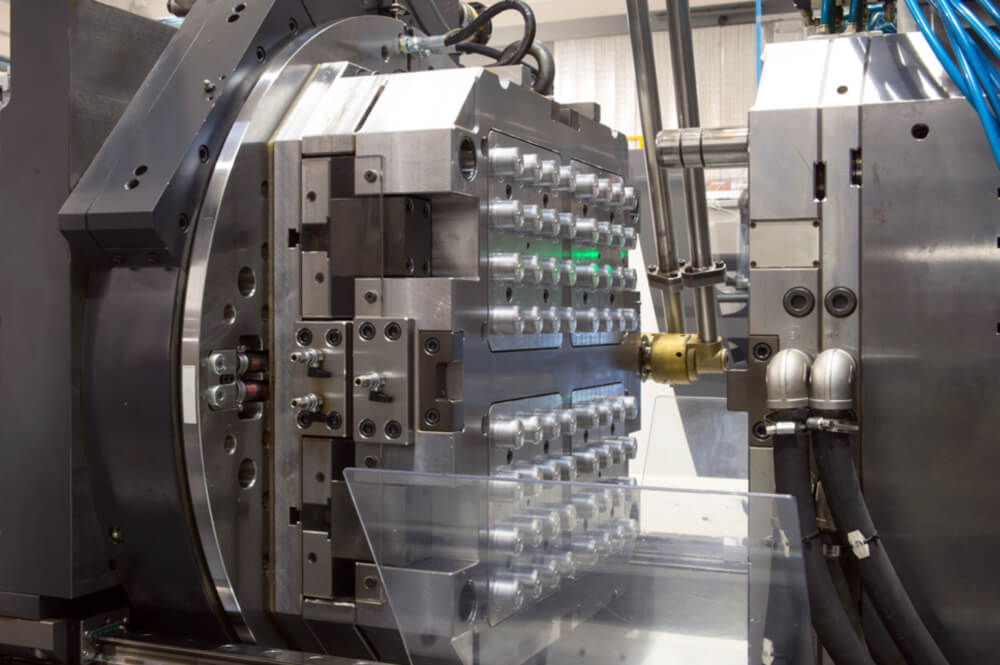

Automated Test Equipment, or ATE, is a rapidly expanding industry. As manufacturing capabilities have scaled up thanks to automated production lines and improved data management practices, a new bottleneck has emerged: testing. Quality control has become the new chokepoint in production, especially in aerospace companies. By expanding your ATE capabilities, you can maintain quality without sacrificing output.

Jan 24, 2022

Before you can bring a new industrial solution to market, it has to be vetted thoroughly. Similarly, to prove that your company can handle massive installations for the public sector, you’ll need to demonstrate your capacity. Expanding your own operations calls for pilot designs and exploratory testing to ensure that your goals are feasible. Regardless of the exact situation, testing your systems and their components is essential. R&D and QC processes can be greatly accelerated with automated test equipment.

Jan 13, 2022

Learn how to automate your test system and customize it to your needs from our expert partner NI.