The industrial landscape is rapidly changing, and collaborative robots, also known as cobots, are at the forefront of this transformation. This article will explore the advantages of using cobots, the challenges of using cobots, and the ways in which cobots are changing the industrial landscape.

What are cobots?

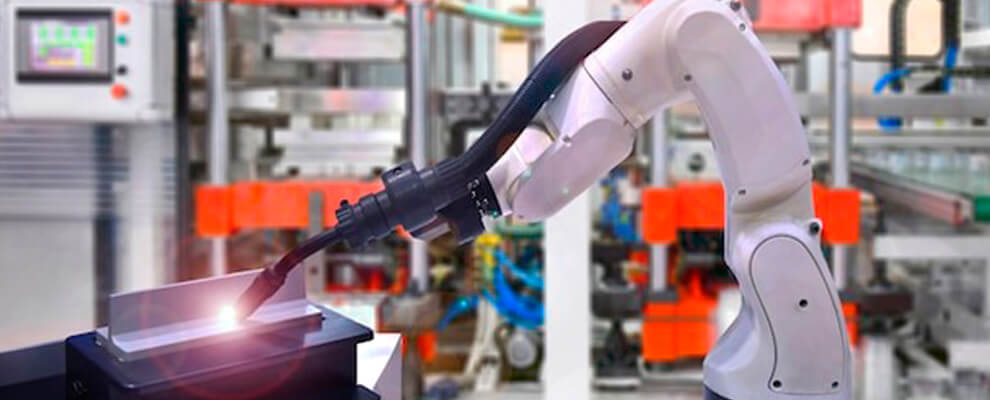

Cobots, or collaborative robots, are robots that are designed to work alongside humans without posing a danger to them. These robots are designed to be easy to program and operate, and are used for a variety of tasks, such as welding, assembling parts, packaging, and more. Cobots are able to work with humans in close proximity, making them ideal for applications where safety is a priority.

In addition to being safe to work with, cobots are also flexible and versatile. They can be programmed to perform a variety of tasks, and can be adapted to changing tasks and environments. This makes them ideal for a wide range of applications.

Advantages of using cobots

One of the primary advantages of using cobots is their ability to work safely alongside humans. Because cobots are programmed to be aware of their surroundings, they are able to work without any risk of injury to humans. This makes them ideal for applications where safety is a key concern.

In addition to safety, cobots are also capable of performing complex tasks with precision and speed. This makes them ideal for high-precision manufacturing processes and applications that require high levels of accuracy and speed, such as welding, assembly, and packaging.

Cobots are also easy to program and operate. They are designed with intuitive user interfaces that make them easy to use, even for those who are unfamiliar with robotics. Additionally, cobots are capable of learning and adapting to new tasks, making them ideal for a wide range of applications.

Finally, cobots are cost-effective. They are able to perform complex tasks quickly and with precision, eliminating the need for expensive labor costs. This makes them an attractive option for businesses looking to reduce costs while still achieving high levels of productivity.

Challenges of using cobots

While there are many advantages to using cobots, there are also some challenges associated with them. One of the primary challenges is the high cost of cobots. While cobots are more cost-effective than traditional labor costs, they still require a significant investment. This can be a significant barrier for businesses that are looking to implement cobots.

Another challenge is the lack of skilled personnel needed to operate cobots. Although cobots are designed to be easy to program and operate, they still require someone with a certain level of expertise in order to operate them. This can be a challenge for businesses that do not have access to skilled personnel.

Finally, cobots can be prone to errors. Cobots are programmed to be aware of their surroundings, but they can still make mistakes. This can lead to costly errors, and can be a challenge for businesses that are looking to maximize efficiency.

Applications of cobots

Cobots are being used in a variety of industries and applications. One of the primary applications of cobots is in manufacturing. Cobots are being used to automate complex tasks, such as welding, assembly, and packaging. In addition, cobots are being used for quality assurance, inspecting parts for defects and ensuring that products meet quality standards.

Cobots are also being used in logistics and transportation. They are being used to automate the loading and unloading of goods from vehicles, as well as the sorting and packing of items. This has enabled businesses to reduce labor costs while still achieving high levels of efficiency.

Finally, cobots are being used in healthcare. They are being used to assist with surgeries and other medical procedures, as well as to provide care to elderly and disabled patients. This has enabled healthcare providers to reduce costs while still providing quality care.

Benefits of cobots in the manufacturing industry

Cobots are transforming the manufacturing industry, and have the potential to revolutionize the way manufacturing is done. One of the primary benefits of using cobots in manufacturing is increased efficiency. Cobots are able to perform complex tasks quickly and with precision, eliminating the need for expensive labor costs. This can help businesses reduce costs while still achieving high levels of productivity.

Cobots are also helping to reduce waste in the manufacturing process. By eliminating the need for human labor, cobots can help to reduce errors and ensure that products meet quality standards. This can help to reduce waste, resulting in a more efficient and cost-effective manufacturing process.

Finally, cobots are helping to make the manufacturing process more flexible and adaptable. Cobots are capable of adapting to changing tasks and environments, making them ideal for a wide range of applications. This makes them an ideal choice for businesses that need to be able to quickly adjust to changing conditions.

Challenges of cobots in the manufacturing industry

While there are many benefits to using cobots in the manufacturing industry, there are also some challenges associated with them. One of the primary challenges is the cost of cobots. While cobots are more cost-effective than traditional labor costs, they still require a significant investment. This can be a significant barrier for businesses that are looking to implement cobots.

Another challenge is the lack of skilled personnel needed to operate cobots. Although cobots are designed to be easy to program and operate, they still require someone with a certain level of expertise in order to operate them. This can be a challenge for businesses that do not have access to skilled personnel.

Finally, cobots can be prone to errors. Cobots are programmed to be aware of their surroundings, but they can still make mistakes. This can lead to costly errors, and can be a challenge for businesses that are looking to maximize efficiency.

How cobots are changing the industrial landscape

Cobots are changing the industrial landscape in a number of ways. One of the primary ways cobots are transforming the industrial landscape is by improving efficiency. Cobots are able to perform complex tasks quickly and with precision, eliminating the need for expensive labor costs. This can help businesses reduce costs while still achieving high levels of productivity.

Cobots are also making the industrial landscape more flexible and adaptable. Cobots are capable of adapting to changing tasks and environments, making them ideal for a wide range of applications. This makes them an ideal choice for businesses that need to be able to quickly adjust to changing conditions.

Finally, cobots are helping to reduce waste in the industrial landscape. By eliminating the need for human labor, cobots can help to reduce errors and ensure that products meet quality standards. This can help to reduce waste, resulting in a more efficient and cost-effective industrial process.

How cobots can help optimize smart manufacturing

Cobots can help optimize smart manufacturing in a number of ways. One of the primary ways cobots can help optimize smart manufacturing is by increasing efficiency. Cobots are able to perform complex tasks quickly and with precision, eliminating the need for expensive labor costs. This can help businesses reduce costs while still achieving high levels of productivity.

Cobots are also helping to reduce waste in the manufacturing process. By eliminating the need for human labor, cobots can help to reduce errors and ensure that products meet quality standards. This can help to reduce waste, resulting in a more efficient and cost-effective manufacturing process.

Finally, cobots can help optimize smart manufacturing by improving the flexibility and adaptability of the manufacturing process. Cobots are capable of adapting to changing tasks and environments, making them ideal for a wide range of applications. This makes them an ideal choice for businesses that need to be able to quickly adjust to changing conditions.

Examples of cobots in the manufacturing industry

Cobots are being used in a variety of manufacturing industries, from automotive to electronics. One example is the automotive industry, where cobots are being used to automate the assembly of parts. This has enabled businesses to reduce labor costs while still achieving high levels of efficiency.

Another example is the electronics industry, where cobots are being used to inspect parts for defects and ensure that products meet quality standards. This has enabled businesses to reduce costs while still ensuring that products meet the highest standards.

Finally, cobots are being used in the food industry, where they are being used to automate the packaging and labeling of products. This has enabled businesses to reduce labor costs while still achieving high levels of efficiency.

Conclusion

Cobots, or collaborative robots, are transforming the industrial landscape, and are at the forefront of this transformation. Cobots are robotic systems that are designed and programmed to work in collaboration with humans. They are capable of performing complex tasks quickly and with precision, while maintaining safety protocols. This article has explored the advantages of using cobots, the challenges of using cobots, and the ways in which cobots are changing the industrial landscape.

Cobots are being used in a variety of industries and applications, from manufacturing to healthcare. They are helping to reduce costs while still achieving high levels of efficiency, and are making the manufacturing process more flexible and adaptable. Finally, cobots can help optimize smart manufacturing by increasing efficiency, reducing waste, and improving the flexibility and adaptability of the manufacturing process.

As the industrial landscape continues to evolve, cobots will continue to play an integral role in the transformation. By unlocking the potential of cobots, businesses can reduce costs while still achieving high levels of productivity.

Are you ready to take advantage of cobots and the potential they have to offer? Contact us today to learn more about how cobots can help optimize your smart manufacturing.