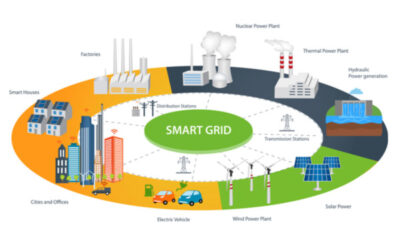

A reliable condition monitoring system can completely transform your industrial operation. You can optimize your maintenance schedule by focusing on the machines that actually need maintenance rather than following a routine that may result in redundant efforts. Even better, you can schedule maintenance for more convenient times. In addition, you can predict when machines are likely to need repair or replacement by gathering data over time. Monitoring your machines’ condition is essential to gain a competitive advantage.

While some modern machines have monitoring components built in, you don’t need to upgrade your factory floor. You can retrofit older machines with specialized instruments at a fraction of the price. An investment in condition monitoring technology yields significant returns due to the relatively low initial expense and massive potential for long-term savings. So, what do you need to make it possible? Let’s look at the most important instruments in a monitoring system.